Easily Set Up HMI Visualizations for Machine Control

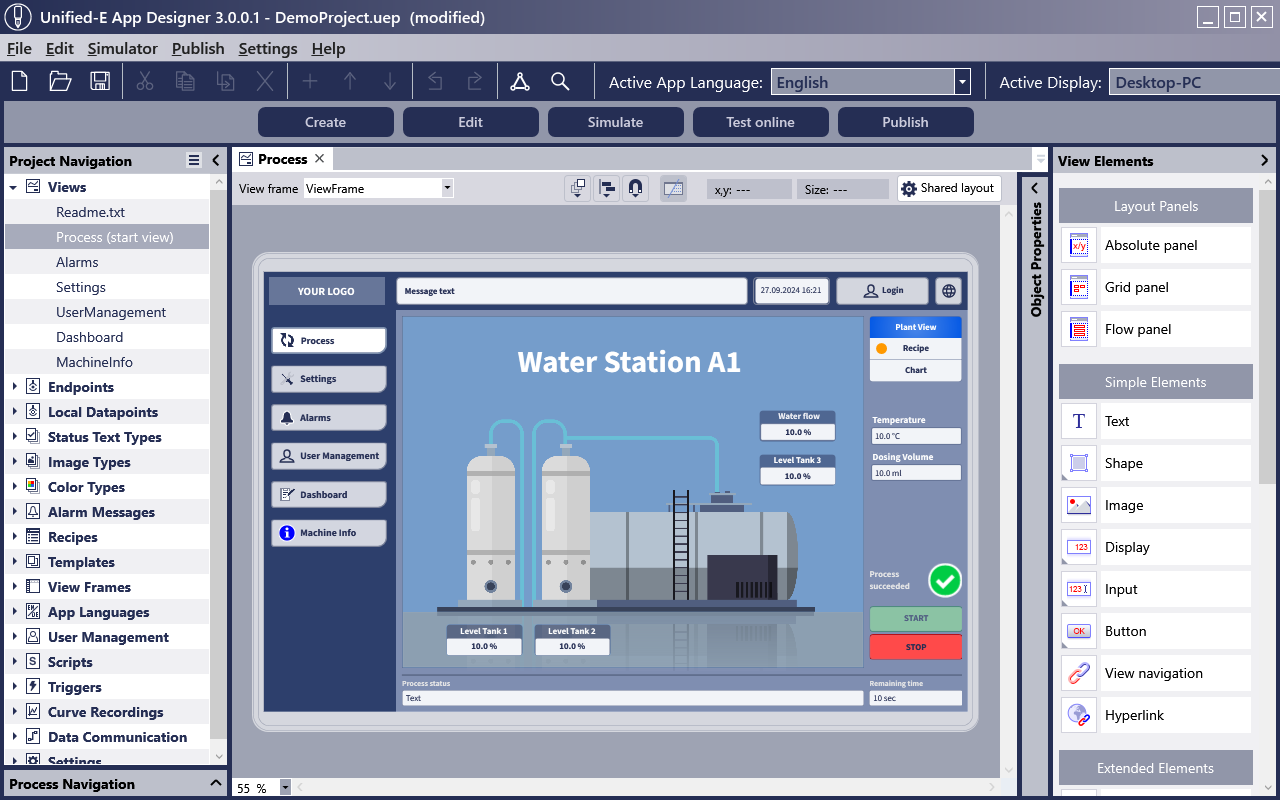

Configuring your machine HMI application begins with Unified-E’s free HMI editor, Unified-E App Designer, available without a license.

If you opt for direct communication between the operator device and the endpoint, simply install the Unified-E Client software on the operator device and register your configured HMI application. That’s it! The registered application can be used without a license for 48 hours, making it perfect for testing and development.

Stationary machine operation - the classic choice for HMI interfaces.

Unified-E for Windows or Android HMI Panels – From Premium to Cost-Effective

Unified-E HMI interfaces run on Windows panel PCs of all performance levels. Additionally, Android HMI panels are supported, which are increasingly being adopted in industrial applications. While Windows panels are a well-known choice for HMIs, Android panels offer a cost-efficient machine control system.

Contact us for recommendations on suitable panel and hardware suppliers.

Download the Unified-E Client for your panel PC, computer, or Android panel based on your platform:

- Windows: Download the Unified-E Client installer for Windows from the download section.

- Android, non-certified (AOSP): The APK file can be downloaded from the download section and manually installed on your Android device.

- Android, Google-certified: Install the Unified-E HMI app via Google Play.

Unified-E also supports Apple’s iOS operating system; however, the Unified-E Client for iOS is primarily used for smartphone remote monitoring and HMI apps for Android & iPhone.

Uninterrupted Long-Term Data Recording for Machine Operation

If machine data such as alarms, diagrams, or CSV recordings need to be stored even after the HMI operator device is turned off, the Unified-E App Manager is the ideal HMI server solution. It is installed on a gateway PC as a server, ensuring that recipe data storage or the alarm archive is centrally managed on the gateway PC.

With this gateway communication setup in the local network, the App Manager operates offline, meaning communication between the operator device and the gateway PC occurs exclusively within the local network. The Unified-E Client on the operator device indirectly accesses the PLC controllers via the Unified-E App Manager.

Data recording functions such as CSV logging or the alarm archive are also available in direct communication. In this case, the data is stored locally on the operator device, such as a Windows panel PC—but only as long as the operator device is powered on.

Fixed-Price Licenses – Tailored to Your Needs

Configuring your HMI machine control system is easy with the HMI editor, Unified-E App Designer, available for free in the download section.

Unified-E is available as a hardware-bound fixed-price license for local machine HMIs (without cloud services). Depending on the license type, it is linked to the gateway PC or operator device and remains valid for the entire hardware lifespan. A license transfer to another operator device is possible twice within the first 10 years after purchase.

During the license period, you receive unlimited update support for the HMI software. This ensures continuous improvements and new features while keeping the Unified-E Client operational even after an operating system update.

For machine operation in a local network, two license types are available:

- Direct License: Ideal if HMI data only needs to be recorded while the HMI is running, meaning no HMI server is required—at a fixed price. This license is activated in the Unified-E Client. During development, a registered operator app can always be used fully for free for 48 hours. To reuse it, the operator app must be re-registered.

- Basic License: Optimal if the operator device is in the local network and long-term recording needs to be uninterrupted—at a fixed price. This license is activated in the Unified-E App Manager. For development, testing can be done with the free developer license.

Detailed information on license types and pricing can be found at Pricing.

Why Choose Unified-E HMI System for Machine Operation?

- Intuitive HMI Creation – Easily create monitoring and plant control interfaces with the Unified-E App Designer

- Flexible Device Support – Windows panel PCs & Android HMI panels

- Direct or Gateway Communication – Optional central HMI server for uninterrupted data logging

- Fixed-Price Licenses – Includes softwareupdate support

- Free development and testing – License required only for production use

Typical Use Cases

- Machine Control for Mechanical Engineering – Intuitive operation via touchscreen

- Plant Engineering – Flexible machine control solutions for complex industrial plants

- Monitoring in Process Automation – Machine monitoring and control of process data, e.g., in the chemical and pharmaceutical industries

- Energy Management – Real-time HMI application of consumption data & load profiles

- Packaging & Production Machines – Optimization & control of production processes