Recipes are our focus!

Recipe Management with the Recipe Table

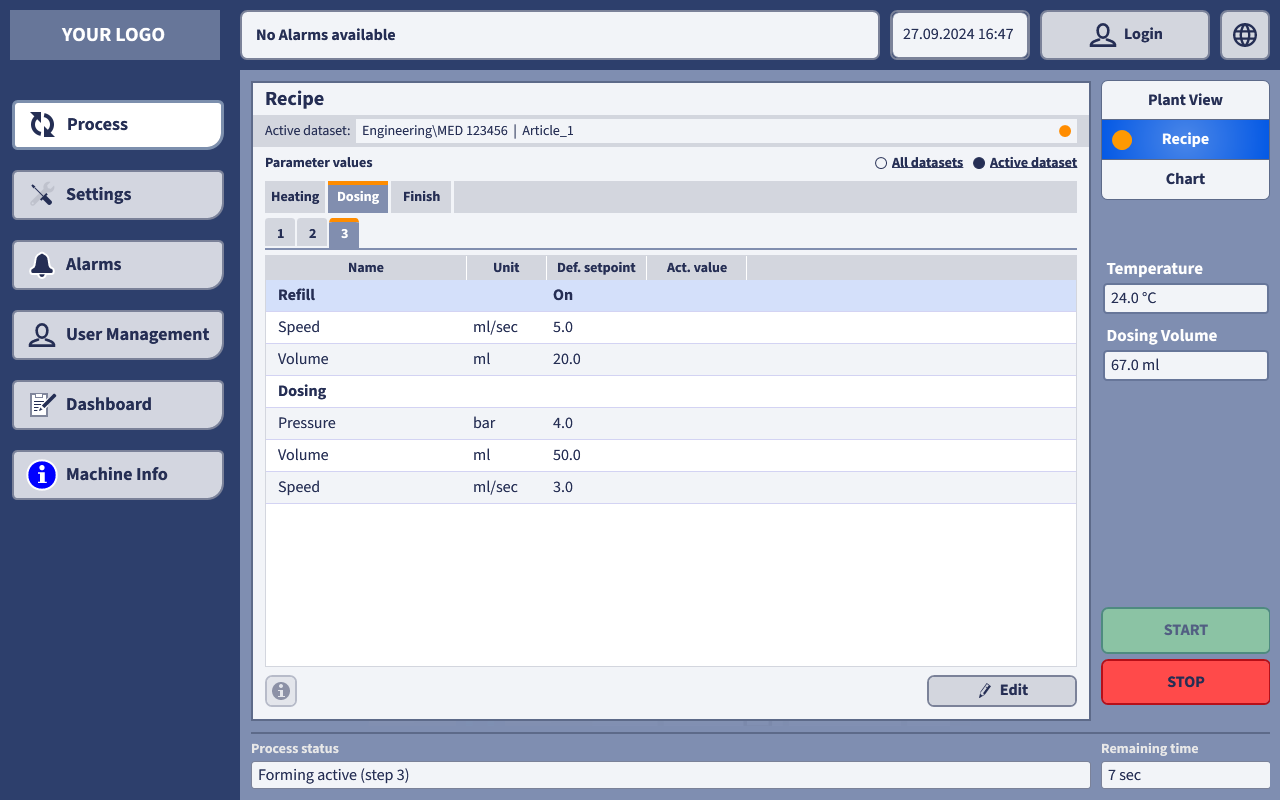

In the HMI visualization, recipes are managed in a recipe table, where recipe datasets with the desired parameters are defined. From this table, the operator loads the desired recipe dataset using the "Activate" function. During this process, the parameters are written from the HMI to the designated PLC variables, also known as load datapoints.

Additionally, the currently activated dataset is displayed in the recipe table. Based on this activated dataset, individual production processes can then be started manually or automatically, depending on the plant or machine.

Recipe parameters can be grouped, making configuration even more convenient and allowing parameters to be displayed in an organized and clear manner.

Recipe Permissions

With the help of permissions, Unified-E can determine whether a user is allowed to create, edit, or activate recipe datasets. The "Adjust" function can be used in the recipe dataset to specify whether operators are allowed to adjust certain parameters without overwriting the original dataset.

The following user roles are commonly found in production operations and could be configured in Unified-E as follows:

- Technician/Engineer:

The technician's task is to define the recipe to achieve the optimal product. They search for and define the ideal parameters for the production process. - Operator:

The operator must execute the production process according to the production order. For this, they must activate the correct recipe. Depending on the plant or machine, they may have the option to adjust certain released parameters before activating the recipe. This function is also called "Adjust before Activating" in the Unified-E environment.

Operators are generally not allowed to modify saved recipe datasets or create new versions. - Administrator:

The administrator can define folder permissions, create new dataset folders, or delete recipe datasets.

Recipe Type vs. Recipe Dataset (Instance)

Recipe datasets, or simply recipes, contain a specific combination of parameters (settings or configurations) to produce a specific product or perform a specific task. A recipe type, on the other hand, defines the structure of the recipe datasets, essentially specifying which parameters should be included in a recipe dataset.

Many production machines know only one recipe type. This defines which parameters are generally necessary for the production process (and not yet the specific values). However, it is also conceivable that an additional recipe type with calibration data, e.g. for heating plates, is defined. When changing the heating plates, the corresponding calibration data must then be loaded from the recipe dataset.

Easily Monitor Production Process Progress

A picture is worth a thousand words. Therefore, plant images are often used to visualize an active process. However, with many recipe parameters and process phases, a plant image can quickly become confusing, and the process status and progress are not easily recognizable.

Unified-E therefore offers the additional option to visualize the running process in the recipe table. For specific parameters associated sensor values can be displayed. Furthermore, parameter groups, steps, and individual parameters can be highlighted in color depending on datapoint values.

The status of the current step is directly visible in the recipe table. This can significantly reduce HMI development time, and you can always keep an eye on your process during production.

Traceability through Versioning

For versioned datasets, a new version is generated each time a changed dataset is saved. This is not only helpful for traceability of production but can also be useful in the R&D phase during product development. The engineer can always revert to old dataset versions and use them as a new basis.

Configure Parameter Visibility at Runtime Dynamically

Parameters can be configured to be visible in the recipe table only when dependent parameters have a specific value. Competitor systems solve this with multiple recipe types (master), but with Unified-E, you can handle such variation with just one recipe type, reducing engineering effort.

Additionally, visibility can be influenced by a datapoint condition (i.e., depending on a PLC variable).

Divide Process into Multiple Visible Steps

If a production process (e.g. a welding or a forming process) has several similar steps in one process run, these can also be treated as steps in the recipe table in Unified-E. Active steps can even be highlighted during the process run, allowing the process progress and status to be easily tracked visually.

Why Choose Unified-E for Your HMI Recipe Management?

- Flexible Recipe Types – configurable in the Unified-E App Designer

- Central Storage & Synchronization – with App Manager for server operation

- Platform Independent – usable on Windows, Android, smartphones & multi-client HMIs

- Quick Product Change – reduced downtime through easy recipe activation

- Live Synchronization & Process Progress Display – full transparency during production

Application Examples for HMI Recipe Management

- Production Machines – Quick switching between different product variants, also suitable for medical technology

- Food & Beverage Industry – Adjustment of mixing ratios or baking times

- Chemical Industry – Control of recipes for precise process control